Izinhlobo eziningi zokukhipha insimbi engagqwali zihamba phambili ezindaweni ezinokhahlo ngenxa yokumelana kwazo nokugqwala okukhethekile. Idizayini yabo eqinile imelana nezimo ezimbi kakhulu, iqinisekisa ukusebenza kahle nokwethembeka. Lawa manifolds ahlanganisa ngaphandle komthungo kui-exhaust system ehlukahlukeneukusetha, okunikeza ukuqina okuphezulu kwezinhlelo zokusebenza zezimoto nezezimboni. Ikhono labo lokusebenza ngokuphumelelayo eduzei-inlet kanye ne-exhaust ehlukahlukeneiziguquli zithuthukisa ukusebenza kahle kuzo zonke izilungiselelo zokusebenza ezahlukahlukene.

Kungani i-Stainless Steel iyisinqumo esingcono kakhulu se-Exhaust Manifolds

Ukumelana Nokugqwala kanye Nokuqukethwe Okuphezulu kwe-Chromium

Insimbi engagqwali igqame njengeimpahla ekahle qeda manifoldsngenxa yokumelana kwayo nokugqwala okukhethekile. Okuqukethwe kwe-chromium ephezulu kunsimbi engagqwali kudlala indima ebalulekile kulesi sakhiwo. I-Chromium ihlangana nomoya-mpilo ukuze yakhe isendlalelo se-chrome-oxide esivikelayo ngaphezulu. Lesi singqimba sisebenza njengesithiyo sokugqwala nezinye izinhlobo zokugqwala, siqinisekisa ubuqotho bezinhlobonhlobo ngisho nasezimweni ezinzima.

Imvelo yokuziphilisa yongqimba lwe-chrome-oxide ithuthukisa ngokwengeziwe ukuqina kwayo. Lapho okungaphezulu kuklwejwa noma konakaliswa, ungqimba luyavuseleleka, lugcine ukuvikeleka. Amabanga anekhabhoni ephansi ensimbi engagqwali, afana no-321 SS, asebenza kahle kakhulu kuma-nifold exhaust. Lawa ma-alloys ahlanganisa i-titanium, eqinisa i-carbide futhi ivimbele izinkinga ezifana nemvula ye-carbide. Lesi sici sibalulekile ekugcineni ukumelana nokugqwala kumazinga okushisa aphakeme, lapho izinto ezijwayelekile zingase zehluleke.

Ithiphu:Ukukhetha insimbi engagqwali enokuqukethwe okuphezulu kwe-chromium kuqinisekisa ukusebenza kwesikhathi eside nokuthembeka kokukhipha okuningi okuvezwe ezimeni ezimbi kakhulu.

Ukuzinza Kwe-Thermal kanye Nokusebenza Kwezinga Lokushisa Eliphezulu

Ama-nifold exhaust asebenza ngaphansi kokushisa okukhulu, ngokuvamile afinyelela amazinga okushisa aphakathi kuka-900°F no-1400°F (482°C kuya ku-760°C). Insimbi engagqwali ihamba phambili ezindaweni ezinjalo ngenxa yokuzinza kwayo okushisayo okumangalisayo. Ngokungafani nezinye izinto, insimbi engagqwali imelana nokuguqulwa futhi igcina ubuqotho bayo besakhiwo ngaphansi kokuchayeka isikhathi eside emazingeni okushisa aphezulu.

Okuqukethwe kwe-chromium ephezulu kunsimbi engagqwali kuvimbela imvula ye-carbide, into eyenzekayo lapho i-chromium iqedwa ohlamvu lwealloy. Lokhu kuncipha kwenza buthaka isendlalelo se-chrome-oxide esivikelayo, okwenza izinto zibe sengozini yokugqwala. Ama-alloys ensimbi engagqwali adizayinelwe izinhlelo zokusebenza ezinezinga eliphezulu lokushisa, njenge-321 SS, anciphisa le ngozi, aqinisekise ukusebenza okungaguquki.

Qaphela:Ukuzinza kwe-thermal kubalulekile kuma-nifold exhaust ezimotweni nasemishinini esebenza ezimeni ezinzima. Insimbi engagqwali iqinisekisa ukwethembeka nokuphepha kulezi zicelo.

Ukuphila Okude kanye Nezindleko Ezinhle Ezimweni Ezinzima

I-stainless steel exhaust manifolds inikezela ngokuphila isikhathi eside okungenakuqhathaniswa, okuwenza abe yinketho engabizi kakhulu ezimbonini. Ukumelana kwabo nokugqwala nokucindezeleka okushisayo kunciphisa isidingo sokushintshwa njalo, konga kokubili isikhathi nemali. Ukuqina kwensimbi engagqwali kuqinisekisa ukuthi imifucumfucu kagesi ingamelana nokuchayeka kusawoti, umswakama, namakhemikhali ngaphandle kokuphazamisa ukusebenza.

Ngaphezu kokuqina kwazo ngokomzimba, izinqwaba zensimbi engagqwali zinomthelela ekusebenzeni kahle. Ikhono labo lokugcina ukusebenza ezindaweni ezeqisayo kunciphisa isikhathi sokuphumula kanye nezindleko zokulungisa. Izimboni ezifana nezimoto, zasolwandle, nezisetshenziswa zezimboni zihlomula kakhuluukwethembeka kwesikhathi eside kwensimbi engagqwaliexhaust manifolds.

I-callout:Ukutshala imali ezintweni eziningi zokukhipha insimbi engagqwali kuqinisekisa ukuqina nokonga kwezindleko, kuzenze zibe ukukhetha okuhlakaniphile kwezindawo ezinokhahlo.

Izici Ezibalulekile Nezinzuzo Zokuphuma Kwensimbi Engenasici

Ukumelana Nosawoti, Umswakama, Namakhemikhali

I-stainless steel exhaust eningi iphuma phambili ezindaweni lapho ukuchayeka kusawoti, umswakama, namakhemikhali kungenakugwenywa. Lezi zimo zivame ukuholela ekugqwaleni kwezinto ezivamile, ezibeka engcupheni ukusebenza nokuqina. Ukumelana ngokwemvelo kwensimbi engagqwali kulezi zici kuqinisekisa ukwethembeka kwesikhathi eside. Isendlalelo se-chrome-oxide esivikelayo esakhiwe okuqukethwe kwayo kwe-chromium ephezulu sisebenza njengesihlangu, sinqanda ukugqwala nokusabela kwamakhemikhali okona impahla.

Izimboni ezifana nezasolwandle nezilwandle zithembele kakhulu kulesi sici. Izindawo zamanzi anosawoti zinokhahlo kakhulu, kodwa izinqwaba zensimbi engagqwali zigcina ubuqotho besakhiwo nokusebenza kwazo. Lokhu kumelana nakho kuzuzisa izimoto ezisebenza ezindaweni ezineqhwa elikhulu, lapho usawoti womgwaqo usheshisa ukugqwala.

Ithiphu:Ukuhlanza njalo kuthuthukisa ukumelana nosawoti kanye namakhemikhali, okuqinisekisa ukusebenza kahle ezimeni eziyinselele.

Idizayini Engasindi Kodwa Eqinile Ngokwesakhiwo

Ama-multifold steel exhaust amaningi ahlanganisa ukwakhiwa okungasindi namandla akhethekile. Le bhalansi ifinyelelwa ngamasu obunjiniyela athuthukile, okuhlanganisa indlela yesici esinqunyiwe (FEM). Ukulingiswa kwe-FEM kuthuthukisa ukwakheka kwe-multifold kanye nezakhiwo ezibonakalayo, kuqinisekisa ubuqotho besakhiwo ngaphandle kokwengeza isisindo esingadingekile.

- Imibono yobunjiniyela ebalulekile:

- Amamodeli we-FEM alingisa imiklamo ehlukahlukene ngaphansi kwezimo zomthwalo nokushisa, aqinisekise ukuqina.

- Ukuhlaziywa kwezinombolo kuthuthukisa umumo we-multifold ukuze uthole ukusebenza okuthuthukisiwe.

- Imiklamo ethuthukisiwe igcina amandla ngenkathi yehlisa ukusetshenziswa kwezinto ezibonakalayo.

Le dizayini engasindi kodwa eqinile ithuthukisa ukusebenza kahle kukaphethiloli futhi inciphisa ubunzima kusistimu yokukhipha umoya. Izimoto ziyazuza ekuphathweni okuthuthukisiwe kanye nokuguga okuncishisiwe ezingxenyeni ezixhunyiwe. Amandla esakhiwo aqinisekisa ukuthi i-manifold imelana nokucindezeleka okushisayo kanye nemithwalo yemishini, ngisho nasezinhlelweni zokusebenza ezinzima.

Ukuqina Okuthuthukisiwe Kokusetshenziswa Kwesikhathi Eside

Ukuqina kuchaza inqwaba yokukhipha insimbi engagqwali. Ikhono labo lokumelana nokugqwala, ukucindezeleka okushisayo, nokugqoka kwemishini kuqinisekisa ukusebenza kwesikhathi eside. Ngokungafani nezinto zendabuko, insimbi engagqwali igcina ukusebenza kwayo isikhathi eside, inciphisa isidingo sokushintshwa.

Izimboni zibeka phambili ukuqina ukuze zinciphise izindleko zesikhathi sokuphumula nezokulungisa. Izinqwaba zensimbi engagqwali ziletha ukusebenza okungaguquki ezindaweni ezinokhahlo, okuhlanganisa izilungiselelo zezimboni ezinezinga eliphezulu lokushisa kanye nezimo zasolwandle ezigqwalayo. Ukuphila kwabo isikhathi eside kubenza babe yisixazululo esingabizi kakhulu sezinhlelo zokusebenza ezidinga ukwethembeka nokuqina.

I-callout:I-Stainless steel exhaust manifolds inikezaukuqina okungenakuqhathaniswa, okubenza babe ukukhetha okuthandwayo ezimbonini ezifuna izixazululo zesikhathi eside.

Izicelo ze-Stainless Steel Exhaust Manifolds

Imboni Yezimoto: Izimoto, Amaloli, Nezimoto Ezisindayo

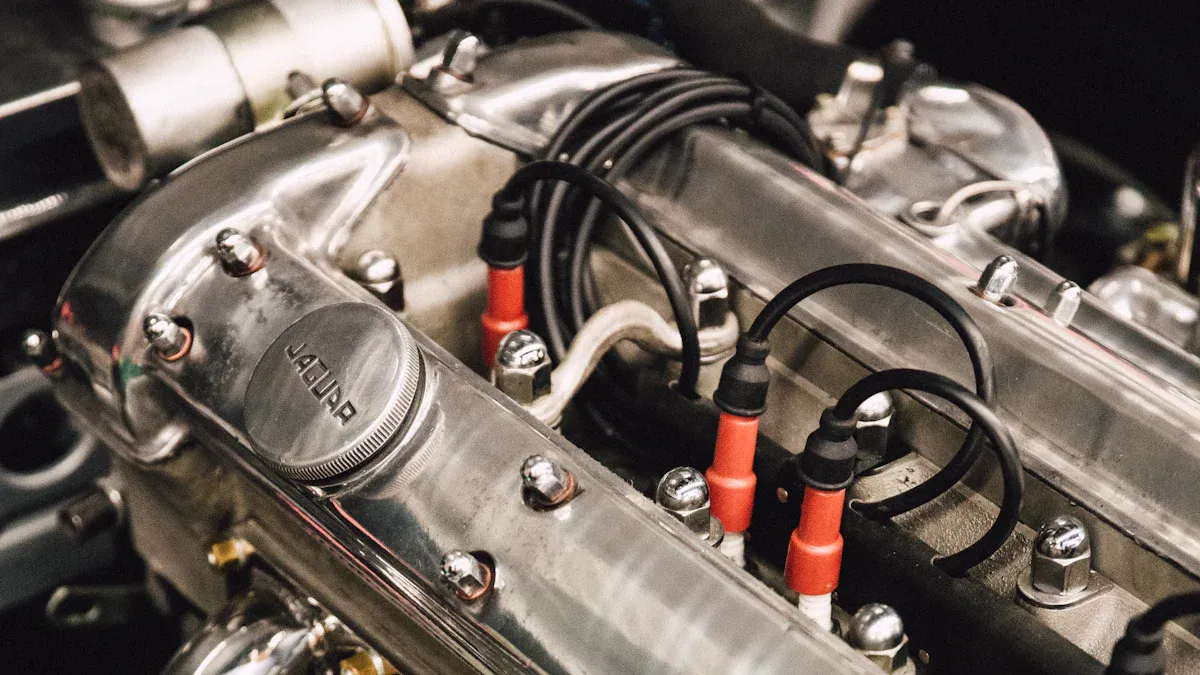

Insimbi engagqwali exhaust manifolds idlala indima ebalulekileimboni yezimoto. Ukumelana nokugqwala kwazo nokuzinza kwe-thermal kuzenza zilungele izimoto, amaloli, nezimoto ezithwala kanzima. Lezi zimoto zivame ukusebenza ezimweni ezimbi kakhulu, njengamazinga okushisa aphezulu kanye nokuchayeka kusawoti womgwaqo. Insimbi engagqwali iqinisekisa ukuthi i-exhaust manifold ihlala isebenza futhi ihlala isikhathi eside ngaphansi kwalezi zinselele. Ukwengeza, umklamo wayo ongasindi wehlisa isisindo sisonke semoto, uthuthukise ukusebenza kahle kukaphethiloli nokusebenza. Abakhiqizi bathembele ensimbi engagqwali ukuze bahlangabezane nezidingo zobunjiniyela bezimoto besimanje, ukuqinisekisa ukwethembeka nokuphila isikhathi eside.

Imvelo Yasolwandle Nasolwandle

Izindawo zasolwandle nezisogwini zinezinselelo eziyingqayizivele, okuhlanganisa ukuchayeka njalo emanzini anosawoti kanye nomswakama. Imishini yokukhipha insimbi engagqwali ihamba phambili kulezi zimo ngenxa yokumelana kwayo okukhethekile nokugqwala. Izikebhe, imikhumbi, nezinkundla zasolwandle ziyazuza ekhonweni lazo lokumelana nemiphumela enzima kasawoti kanye nomswakama. Lokhu kuqina kunciphisa izidingo zokunakekelwa futhi kwandisa isikhathi sokuphila kwemishini. Amandla esakhiwo sensimbi engagqwali futhi aqinisekisa ukuthi ingakwazi ukubhekana nezingcindezi zokusebenza zasolwandle, ikwenze kube ukukhetha okuncanyelwayo kulezi zinhlelo zokusebenza ezinzima.

Imishini Yezimboni Nemishini

Imishini yezimboni nemishini ivamise ukusebenza ezindaweni ezinamazinga okushisa aphezulu, ukuchayeka kwamakhemikhali, kanye nengcindezi yemishini. Insimbi engagqwali exhaust manifolds inikezaukuqina nokuthembekaezidingekayo ezimweni ezinjalo. Ukumelana nokugqwala nokucindezeleka okushisayo kuqinisekisa ukusebenza okungaguquki, ngisho nasezilungiselelweni zezimboni eziyinselele kakhulu. Izimboni ezifana nokukhiqiza, ukukhiqiza ugesi, kanye nezokwakha zithembele ezinhlobonhlobo zensimbi engagqwali ukuze zigcine ukusebenza kahle. Ukuphila isikhathi eside kwento kanye nezidingo zokunakekelwa okuphansi kuyenza ibe yisixazululo esingabizi kakhulu sezinhlelo zokusebenza zezimboni.

Amathiphu Okulungisa Ama-Manifolds Okukhipha Insimbi Engagqwali

Ukuhlanza Njalo Ukuze Uvimbele Ukugqwala Kwakheka

Ukuhlanza okujwayelekile kubalulekile ukuze kugcinwe ukusebenza nempilo ende yokukhipha insimbi engagqwali. Uthuli, ukungcola, nezinsalela zamakhemikhali zinganqwabelana phezulu ngokuhamba kwesikhathi, okungase kube sengozini yokuvikela ungqimba lwe-chrome-oxide. Ukuhlanza kususa lezi zinto ezingcolile futhi kuvimbela ukugqwala kokwakheka.

Ukuhlanza ngempumelelo:

- Sebenzisa indwangu ethambile noma isipontshi ngensipho ethambile namanzi.

- Gwema izinto ezilimazayo ezingase zinwaye indawo.

- Hlanza kahle ukuze ususe noma yiziphi izinto zokuhlanza.

Ithiphu:Ukuze uthole amabala anenkani, sebenzisa isicoci sensimbi engagqwali esidizayinelwe izingxenye zezimoto. Lokhu kuqinisekisa ukuthi i-multifold igcina ukubukeka kwayo okuphucuziwe kanye nezakhiwo zokuvikela.

Ukuhlolwa Kokulimala Ezindaweni Ezinzima

Ukuhlola okuvamile kusiza ukuhlonza izinkinga ezingase zibe khona ngaphambi kokuba zikhule. Izindawo ezinokhahlo, njengalezo ezinomswakama ophezulu noma ezivezwa usawoti, zingabangela ingcindezi noma umonakalo omncane kokuningi. Ukutholwa kusenesikhathi kuqinisekisa ukulungiswa ngesikhathi futhi kuvimbela ukushintshwa okumba eqolo.

Izindawo ezibalulekile okufanele zihlolwe zihlanganisa:

- Amalunga ashiselwe ukuqhekeka noma izimpawu zokuguga.

- Ukushintsha umbala wobuso, okungase kubonise ukushisa ngokweqile.

- Amaphoyinti okukhweza amabhawodi axegayo noma ukungahambi kahle.

Qaphela:Hlela ukuhlolwa ngesikhathi sokunakekelwa kwemoto okujwayelekile ukuze uqinisekise ukusebenza okungaguquki.

Ukufakwa Okufanelekile Ukugwema Ukucindezeleka Nemifantu

Ukufaka okulungile kudlala indima ebalulekile ekuqineni kwezinto eziningi. Ukukhweza okungalungile kungaholela kumaphuzu okucindezeleka, okungase kubangele ukuqhekeka noma ukuguqulwa ngaphansi kwamazinga okushisa aphezulu. Ukulandela imihlahlandlela yomkhiqizi kuqinisekisa ukulingana okuvikelekile nokungenaso ingcindezi.

Imikhuba ehamba phambili yokufaka:

- Sebenzisa izilungiselelo zetorque ezinconyiwe zamabhawudi.

- Qinisekisa ukuhambisana kahle nesistimu yokukhipha umoya.

- Gwema ukuqinisa ngokweqile, okungase kucindezele impahla.

I-callout:Izinsizakalo zokufaka ezichwepheshile ziqinisekisa ukusebenza kahle futhi zandisa isikhathi sokuphila sokuphuma kwensimbi engenasici.

Insimbi engagqwali eminingi yokukhipha umoya inikeza ukumelana nokugqwala okungenakuqhathaniswa nokuqina, okuwenza alungele izindawo ezinokhahlo. Ukuguquguquka kwabo kuhlanganisa izinhlelo zokusebenza zezimoto, zasolwandle nezimboni. Ubuchwepheshe buka-Ningbo Werkwell kwezokukhiqiza buqinisekisa imikhiqizo esezingeni eliphezulu ehambisana nezidingo zemboni. Ukuzibophezela kwabo ekunembeni nasekusunguleni izinto kuqinisekisa izixazululo ezinokwethenjelwa ezidingweni ezihlukahlukene zokusebenza.

FAQ

Yini eyenza ama-multifold steel exhaust alungele izindawo ezinokhahlo?

Insimbi engagqwali imelana nokugqwala, iphatha izinga lokushisa eliphezulu, futhi igcina ubuqotho besakhiwo. Ukuqina kwayo kuqinisekisa ukusebenza okuthembekile ezimeni eziyinselele.

I-Ningbo Werkwell iqinisekisa kanjani ikhwalithi yomkhiqizo?

I-Werkwell isebenzisa izindawo zokuhlola ezithuthukile, amaqembu e-QC anolwazi, nobunjiniyela obunembile. Izinsizakalo zabo ze-OEM/ODM zihlangabezana nezidingo zamakhasimende ezahlukahlukene.

Ingabe i-stainless steel exhaust manifolds ingasetshenziswa ezinhlelweni zasolwandle?

Yebo, insimbi engagqwali imelana nokuchayeka emanzini anosawoti kanye nomswakama. Ukumelana nokugqwala kwayo kuyenza ifanelekele izikebhe, imikhumbi, namapulatifomu asogwini.

Isikhathi sokuthumela: Apr-29-2025