Iindlela ezininzi zokukhupha intsimbi engenazintsimbi zigqwesa kwiindawo ezirhabaxa ngenxa yokumelana kwazo nomhlwa okukhethekileyo. Uyilo lwabo olomeleleyo lumelana neemeko ezinzima, luqinisekisa ukusebenza kakuhle kunye nokuthembeka. Ezi manifolds zidibanisa ngokungenamthungo kwiinkqubo yokukhupha izinto ezininziukuseta, ukunika ukuqina okuphezulu kwizicelo zeemoto kunye nezoshishino. Ukukwazi kwabo ukusebenza ngokufanelekileyo ecaleniukungena kunye nokukhupha okuninziabaguquli baphucula ukusebenza kakuhle kuzo zonke iisetingi zokusebenza ezahlukeneyo.

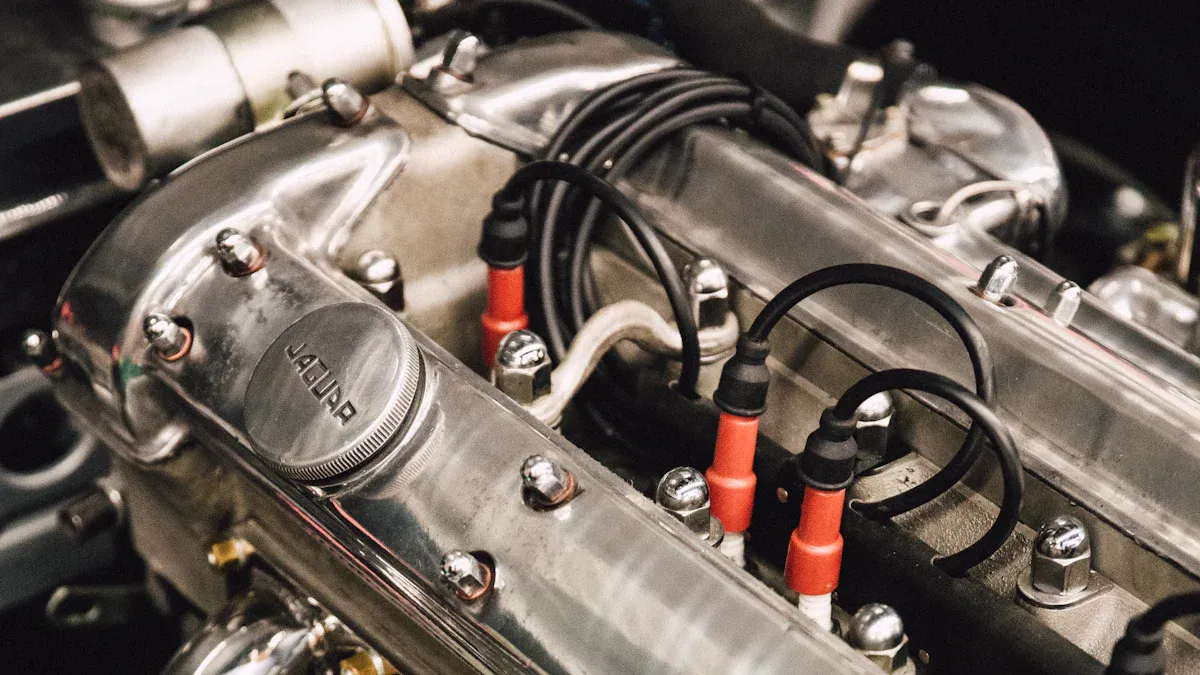

Kutheni le nto iStainless Steel ilolona khetho lulungileyo lokuPhuma iiManifolds

Ukuchasa ukonakala kunye noMxholo oPhezulu weChromium

Intsimbi engatyiwayo igqame njengeimathiriyeli efanelekileyo yokukhupha ii-manifoldsngenxa yokunganyangeki kwayo okugqwesileyo. Umxholo ophezulu wechromium kwintsimbi engenasici udlala indima ebalulekileyo kule propati. I-Chromium idibana neoksijini yenze umaleko okhuselayo we-chrome-oxide kumphezulu. Lo maleko usebenza njengesithintelo kwirusi kunye nezinye iintlobo zomhlwa, uqinisekisa ingqibelelo yobuninzi beemeko ezingqongileyo.

Ubume bokuziphilisa bomgangatho we-chrome-oxide kwandisa ngakumbi ukuqina kwayo. Xa umphezulu ukrwela okanye wonakaliswe, umaleko uphinda uhlaziye, ugcine ukhuseleko. Amanqanaba ekhabhoni ephantsi ensimbi engenasici, afana ne-321 SS, asebenza ngokukodwa kwii-manifolds zokukhupha. Ezi alloys ziquka i-titanium, ezinzisa i-carbides kwaye inqande imiba efana nemvula ye-carbide. Olu phawu lubalulekile ekugcineni ukuxhathisa umhlwa kumaqondo obushushu aphezulu, apho imathiriyeli eqhelekileyo inokusilela.

Ingcebiso:Ukukhetha insimbi engenasici enomxholo ophezulu we-chromium kuqinisekisa ukusebenza kwexesha elide kunye nokuthembeka kweendlela zokukhupha ezivezwe kwiimeko ezinzima.

Ukuzinza kweThermal kunye nokuSebenza okuPhakamileyo

I-exhaust manifolds isebenza phantsi kobushushu obukhulu, amaxesha amaninzi ifikelela kumaqondo obushushu aphakathi kwe-900°F kunye ne-1400°F (482°C ukuya kuma-760°C). Insimbi engenasici igqwesa kwiindawo ezinjalo ngenxa yokuzinza kwayo okumangalisayo kwe-thermal. Ngokungafaniyo nezinye izinto, insimbi engenasici iyamelana ne-deformation kwaye igcina ingqibelelo yayo yesakhiwo phantsi kokuvezwa kwexesha elide kumaqondo aphezulu.

Isiqulatho sechromium esiphezulu kwintsimbi engatyiwa sinqanda imvula ye-carbide, into eyenzekayo xa i-chromium iphelile kwiinkozo ze-alloy. Oku kuncipha kunciphisa i-chrome-oxide layer ekhuselayo, okwenza izinto eziphathekayo zisengozini yokubola. I-alloys yensimbi engenasici eyenzelwe izicelo eziphezulu zokushisa, ezifana ne-321 SS, iyanciphisa le mngcipheko, iqinisekisa ukusebenza okuhambelanayo.

Phawula:Ukuzinza kwe-Thermal kubalulekile kwiindlela ezininzi zokukhupha kwizithuthi kunye noomatshini abasebenza kwiimeko ezinzima. Insimbi engenasici iqinisekisa ukuthembeka kunye nokhuseleko kwezi zicelo.

Ubomi obude kunye nokuSebenza kweNdleko kwiiMeko eziQhekekileyo

Iintlobo ezininzi zentsimbi yokukhupha intsimbi zinika ubomi obude obungenakuthelekiswa nanto, nto leyo ezenza zibe lukhetho olungabizi kakhulu kumashishini. Ukuxhathisa kwabo kwi-corrosion kunye noxinzelelo lwe-thermal kunciphisa isidingo sokutshintshwa rhoqo, konga ixesha kunye nemali. Ukomelela kwentsimbi engenastainless iqinisekisa ukuba i-epoust manifolds inokumelana nokuvezwa kwityuwa, ukufuma, kunye neekhemikhali ngaphandle kokubeka esichengeni ukusebenza.

Ukongeza kokomelela kwabo ngokomzimba, izinto ezininzi zensimbi ezingenasici zinegalelo ekusebenzeni kakuhle. Ukukwazi kwabo ukugcina ukusebenza kwiindawo ezigqithiseleyo kunciphisa ixesha lokunciphisa kunye neendleko zokulungisa. Imizi-mveliso efana neemoto, zaselwandle, kunye nezixhobo zemizi-mveliso zixhamla kakhulu kwiukuthembeka kwexesha elide lensimbi engenasicigqiba ezininzi.

Biza ngaphandle:Utyalo-mali kwizinto ezininzi zokukhupha insimbi engenasici ziqinisekisa ukuqina kunye nokugcinwa kweendleko, kubenza babe lukhetho olunobulumko kwiindawo ezirhabaxa.

Iimpawu eziphambili kunye neeNzuzo zokuSebenza kweeNsimbi ezingenazintsimbi eziManifolds

Ukuxhathisa iTyuwa, ukufuma, kunye neMichiza

Izinto ezininzi zokukhupha intsimbi emdaka ziyagqwesa kwindawo apho ukuvezwa kwetyuwa, ukufuma, kunye neekhemikhali kungenakuthintelwa. Ezi meko zihlala zikhokelela kwi-corrosion kwizinto eziqhelekileyo, ukuphazamisa ukusebenza kunye nokuqina. Ukuchasana okukhoyo kwensimbi engenasici kwezi zinto kuqinisekisa ukuthembeka kwexesha elide. Uluhlu olukhuselayo lwe-chrome-oxide olwenziwe ngumxholo wayo ophezulu we-chromium lusebenza njengekhuselo, lukhusela i-rust kunye neekhemikhali eziphendulayo ezithobisa izinto.

Imizi-mveliso efana nolwandle kunye ne-offshore ixhomekeke kakhulu kolu phawu. Iimeko ezingqongileyo zamanzi etyuwa zinoburhalarhume kakhulu, kodwa ii-manifolds zentsimbi engenastainless zigcina imfezeko yolwakhiwo kunye nokusebenza kwazo. Oku kuxhathisa kukwanceda izithuthi ezisebenza kwimimandla enekhephu elikhulu, apho ityuwa yendlela inyusa umhlwa.

Ingcebiso:Ukucoca rhoqo kwandisa ukuxhathisa ityuwa kunye neekhemikhali ezininzi, ukuqinisekisa ukusebenza kakuhle kwiimeko ezinzima.

Uyilo oluKhaphukhaphu kodwa olomeleleyo

Ii-manifolds zokukhupha intsimbi engenasici zidibanisa ulwakhiwo olukhaphukhaphu kunye namandla akhethekileyo. Olu lungelelwaniso luphunyezwa ngobuchule bobunjineli obuphambili, kubandakanywa nendlela yokuphela kwento (FEM). Ukulinganisa kwe-FEM kwandisa ubume obuphindaphindeneyo kunye neempawu zemathiriyeli, ziqinisekisa imfezeko yesakhiwo ngaphandle kokongeza ubunzima obungeyomfuneko.

- Iimbono zobunjineli eziphambili:

- Iimodeli ze-FEM zilinganisa uyilo olwahlukeneyo phantsi komthwalo kunye neemeko zobushushu, ziqinisekisa ukuqina.

- Uhlalutyo lwamanani lucokisa ubume be-manifold kuphuculo lokusebenza.

- Uyilo olulungiselelwe lugcina amandla ngelixa lunciphisa ukusetyenziswa kwezinto.

Olu yilo lukhaphukhaphu kodwa lomelele luphucula ukusebenza kakuhle kwamafutha kwaye lucuthe ubunzima kwinkqubo yokukhupha umoya. Izithuthi zixhamla ekuphatheni okuphuculweyo kunye nokunciphisa ukunxiba kumacandelo adibeneyo. Amandla okwakhiwa aqinisekisa ukuba i-manifold imelana noxinzelelo lwe-thermal kunye nemithwalo yemishini, nakwizicelo ezifunwayo.

Ukomelezwa koKuhlala ixesha elide

Ukomelela kuchaza iindlela ezininzi zokukhupha intsimbi. Ukukwazi kwabo ukuxhathisa i-corrosion, uxinzelelo lwe-thermal, kunye nokugqoka oomatshini kuqinisekisa ukusebenza kwexesha elide. Ngokungafaniyo nezixhobo zendabuko, insimbi engenasici igcina ukusebenza kwayo ixesha elide, ukunciphisa imfuno yokutshintshwa.

Amashishini abeka phambili ukuqina ukuze kuncitshiswe ixesha lokuphumla kunye neendleko zokugcina. Ii-manifolds zensimbi ezingenasici zihambisa ukusebenza okuhambelanayo kwiindawo ezibuhlungu, kubandakanywa ubushushu obuphezulu bemizi-mveliso kunye neemeko ezinobungozi zaselwandle. Ubomi babo obude bubenza babe sisisombululo esinexabiso eliphezulu kwizicelo ezifuna ukuthembeka kunye nokuqina.

Biza ngaphandle:Iintlobo ezininzi zentsimbi yokukhupha intsimbi zinikaukuqina okungahambelaniyo, okubenza ukuba babe ukhetho olukhethwayo kumashishini afuna izisombululo zexesha elide.

Usetyenziso lweziNtsimbi zeNtsimbi eNgena-Stainless

Umzi mveliso weemoto: Iimoto, iilori, kunye neZithuthi zoMsebenzi onzima

Iintlobo ezininzi zentsimbi yokukhupha intsimbi zidlala indima ebalulekileyoishishini leemoto. Ukunganyangeki kwe-corrosion kunye nokuzinza kwe-thermal kubenza balungele iimoto, iilori, kunye nezithuthi ezinzima. Ezi zithuthi zihlala zisebenza kwiimeko ezinzima, ezifana nobushushu obuphezulu kunye nokuvezwa kwetyuwa yendlela. Insimbi engenasici iqinisekisa ukuba ukukhupha okuninzi kuhlala kusebenza kwaye kuhlala ixesha elide phantsi kwale mingeni. Ukongezelela, uyilo lwayo olulula lunciphisa ubunzima obupheleleyo besithuthi, ukuphucula ukusebenza kakuhle kwamafutha kunye nokusebenza. Abavelisi baxhomekeke kwinsimbi engenasici ukuze bahlangabezane neemfuno zobunjineli beemoto zanamhlanje, ukuqinisekisa ukuthembeka kunye nokuphila ixesha elide.

INdawo yaseLwandle kunye ne-Offshore

Imimandla yaselwandle nekude nonxweme inika imiceli mngeni eyodwa, kuquka ukuchanabeka rhoqo kumanzi anetyuwa nokufuma. Iintlobo ezininzi zokukhupha insimbi engenasici zigqwesa kwezi meko ngenxa yokuxhathisa kwazo okukhethekileyo ekudlekeni. Izikhephe, iinqanawa, kunye namaqonga angaphesheya axhamla kubuchule bazo bokumelana neziphumo ezibi zetyuwa nokufuma. Oku kuqina kunciphisa iimfuno zokugcinwa kwaye kwandisa ixesha lokuphila kwesixhobo. Amandla olwakhiwo lwentsimbi engenastainless ikwaqinisekisa ukuba inokumelana noxinzelelo lwemishini yokusebenza yaselwandle, oko kuyenza ibe lolona khetho lukhethwayo kwezi zicelo zinzima.

Izixhobo zoShishino kunye noomatshini

Izixhobo zemizi-mveliso kunye noomatshini bahlala besebenza kwindawo ezinobushushu obuphezulu, ukuvezwa kweekhemikhali, kunye noxinzelelo lomatshini. Intsimbi yokukhupha iimanifolds ezininzi zibonelelaukuqina kunye nokuthembekaezifunekayo kwiimeko ezinjalo. Ukuchasana kwabo kwi-corrosion kunye noxinzelelo lwe-thermal kuqinisekisa ukusebenza okungaguqukiyo, nakwezona zicwangciso zemizi-mveliso ezinzima. Imizi-mveliso efana neyokuvelisa, ukuvelisa amandla, kunye nokwakha ixhomekeke kwizinto ezininzi zentsimbi engatyiwayo ukugcina ukusebenza kakuhle. Ubomi obude bezinto eziphathekayo kunye neemfuno zokugcinwa okuphantsi zenza isisombululo esineendleko ezisebenzayo kwizicelo zoshishino.

Iingcebiso zoLondolozo lweeManifolds zokuPhuma kweNsimbi engenaNsimbi

Ukucocwa Rhoqo Ukunqanda ukuMhlwa kwaKhe

Ukucoca ngokuqhelekileyo kubalulekile ukugcina ukusebenza kunye nexesha elide lokukhupha insimbi engenasici. Uthuli, ukungcola, kunye neentsalela zeekhemikhali zinokuqokelelana phezu komhlaba ngokuhamba kwexesha, okunokuthi kubeke esichengeni umaleko we-chrome-oxide okhuselayo. Ukucoca kususa ezi zingcolisi kwaye kuthintela ukwakheka komhlwa.

Ukucoca ngokusebenzayo:

- Sebenzisa ilaphu elithambileyo okanye isipontshi ngesepha ethambileyo kunye namanzi.

- Ziphephe izinto ezirhabaxa ezinokukrwela umphezulu.

- Hlanza ngokucokisekileyo ukuze ususe naziphi na izinto zokucoca.

Ingcebiso:Kumabala anenkani, sebenzisa isicoci sentsimbi estainless eyenzelwe ngokukodwa iindawo zemoto. Oku kuqinisekisa ukuba i-manifold igcina imbonakalo yayo ekhazimlisiweyo kunye neempawu zokukhusela.

Ukuhlolwa komonakalo kwiNdawo eziBungqwabalala

Ukuhlolwa rhoqo kunceda ukuchonga imiba enokubakho ngaphambi kokuba inyuke. Iimeko ezirhangqe, ezifana nezo ezinomswakama ophezulu okanye ukubonakaliswa kwetyuwa, kunokubangela uxinzelelo okanye umonakalo omncinci kwizinto ezininzi. Ukufunyaniswa kwangethuba kuqinisekisa ukulungiswa kwangexesha kwaye kuthintele ukutshintshwa kweendleko.

Iindawo eziphambili ekufuneka zihlolwe ziquka:

- Amalungu adityanisiweyo okuqhekeka okanye iimpawu zokuguga.

- Ukutshintsha kombala womphezulu, okunokubonisa ukufudumeza okugqithisileyo.

- Amanqaku okunyuka kwiibholithi ezikhululekileyo okanye ukungahambi kakuhle.

Phawula:Ukuhlolwa kweshedyuli ngexesha lokugcinwa kwemoto yesiqhelo ukuqinisekisa ukusebenza okufanayo.

Ufakelo olululo ukuze ugweme uxinzelelo kunye nokuqhekeka

Ufakelo oluchanekileyo ludlala indima ebalulekileyo ekomeleleni kwezinto ezininzi. Ukunyuka okungafanelekanga kunokukhokelela kwiindawo zokuxinzelela, ezinokubangela ukuqhekeka okanye ukuguqulwa phantsi kwamaqondo okushisa aphezulu. Ukulandela izikhokelo zomenzi kuqinisekisa ukhuseleko olukhuselekileyo nolungenaxinzelelo.

Eyona ndlela yokuhlohla:

- Sebenzisa iisetingi zetorque ezicetyiswayo kwiibholithi.

- Qinisekisa ukulungelelaniswa okufanelekileyo kunye nenkqubo yokukhupha.

- Kuphephe ukuqina ngokugqithisileyo, okunokungcungcuthekisa izinto.

Biza ngaphandle:Iinkonzo zofakelo lobuchwephesha ziqinisekisa ukusebenza ngokugqibeleleyo kwaye zandise ubomi bokuphuma kwentsimbi engenasici.

Izinto ezininzi zokukhupha intsimbi engenaziphene zibonelela ngokumelana nomhlwa kunye nokuqina, oko kubenza balungele imeko engqongileyo. Ukuguquguquka kwabo kuchaphazela iimoto, zaselwandle kunye nezicelo zemizi-mveliso. Ubungcali bukaNingbo Werkwell kwimveliso buqinisekisa iimveliso ezikumgangatho ophezulu ezilungiselelwe iimfuno zeshishini. Ukuzibophelela kwabo ekuchanekeni nasekuqaliseni izinto ezintsha kuqinisekisa izisombululo ezithembekileyo kwiimfuno ezahlukeneyo zokusebenza.

FAQ

Yintoni eyenza ukuba izinto ezininzi zokukhupha intsimbi zilungele iimeko ezingqongileyo ezirhabaxa?

Intsimbi engatyiwayo ixhathisa ukubola, iphatha amaqondo obushushu aphezulu, kwaye igcina isidima solwakhiwo. Ukuqina kwayo kuqinisekisa ukusebenza okuthembekileyo kwiimeko ezinzima.

UNingbo Werkwell uwuqinisekisa njani umgangatho wemveliso?

U-Werkwell usebenzisa amaziko ovavanyo oluphezulu, amaqela anamava e-QC, kunye nobunjineli obuchanekileyo. Iinkonzo zabo ze-OEM/ODM zihlangabezana neemfuno ezahlukeneyo zabathengi.

Ngaba izinto ezininzi zokukhupha intsimbi engatyiwayo zingasetyenziswa kusetyenziso lwaselwandle?

Ewe, intsimbi engatyiwayo iyamelana nokuvezwa kwamanzi etyuwa kunye nokufuma. Ukumelana nomhlwa kuyenza ilungele izikhephe, iinqanawa, kunye namaqonga angaphesheya kolwandle.

Ixesha lokuposa: Apr-29-2025